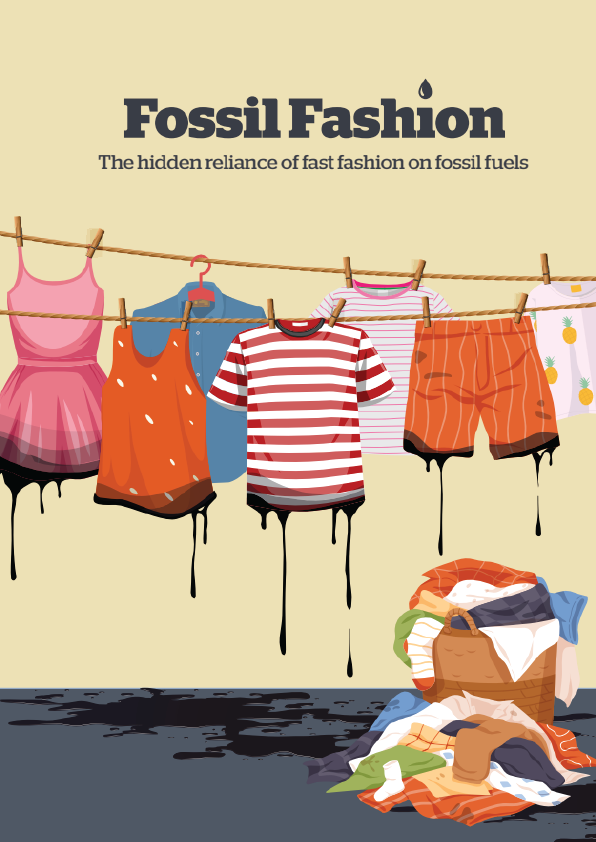

Dependence on fossil fuels

Production of cheap synthetic fibres not only enables low-quality, throwaway fashion – it also makes the fashion industry highly dependent on continued fossil-fuel extraction. The production of synthetic fibres for the textile industry currently accounts for 1.35% of global oil consumption. This exceeds the annual oil consumption of Spain. Numerous studies have also shown that the oil and gas industry is betting on burgeoning production of plastic (which includes synthetic fibres) as a key future revenue stream, as demand for oil from the energy and transport sectors declines.3 BP’s energy scenario presumes plastic production will account for 95% of future growth in demand for oil demand, while the International Energy Agency (IEA) predicts petrochemicals will represent up to 50% of growth in oil demand by 2050 and 4% in the projected growth of gas demand.

We observe similar market projections in the textile sector. It is now estimated that synthetic fibres will grow from 69% to 73% of total fibre production globally by 2030, with polyester accounting for 85% of this. In other words, if the fashion industry continues with business as usual, in less than 10 years, almost three-quarters of our textiles will be produced from fossil fuels. What is more, these fossil fuels are getting dirtier, 4 already coming from fracked gas and even with projects in the pipeline to produce polyester from coal. In 2015, polyester production for textiles alone was responsible for emissions of over 700 million tonnes of carbon dioxide (CO2) equivalent5 – similar to the annual greenhouse gas (GHG) emissions of Mexico6 or 180 coal-fired power plants. This is projected to nearly double by 2030, reaching twice the GHG emissions of Australia.A If these expansion plans go ahead, the textile sector’s emissions could grow rapidly and undermine the climate commitments of fashion brands.

The recycling red herring

Recycling will not solve fast fashion’s problems, nor will it curb the exponential growth in the use of synthetic fibres. Currently, less than 1% of clothes are recycled to make new clothes, and the share of recycled polyester is declining; while it accounted for 14% in 2019,7 this will in fact decrease to 7.9% of overall polyester production by 2030.8 Furthermore, virtually all recycled polyester in clothing comes not from recycled garments, but from recycled plastic bottles. Legislation and voluntary commitments by consumer goods companies means there will be more competition for recycled PET. With limited options for viable fibre-to-fibre polyester recycling, at the end of its life this polyester will be sent to landfill or burnt. Turning polyethylene terephthalate (PET) bottles into recycled polyester fibre therefore represents a one-way ticket to disposal, while this material should instead remain in a closed-loop bottle-to-bottle recycling system.

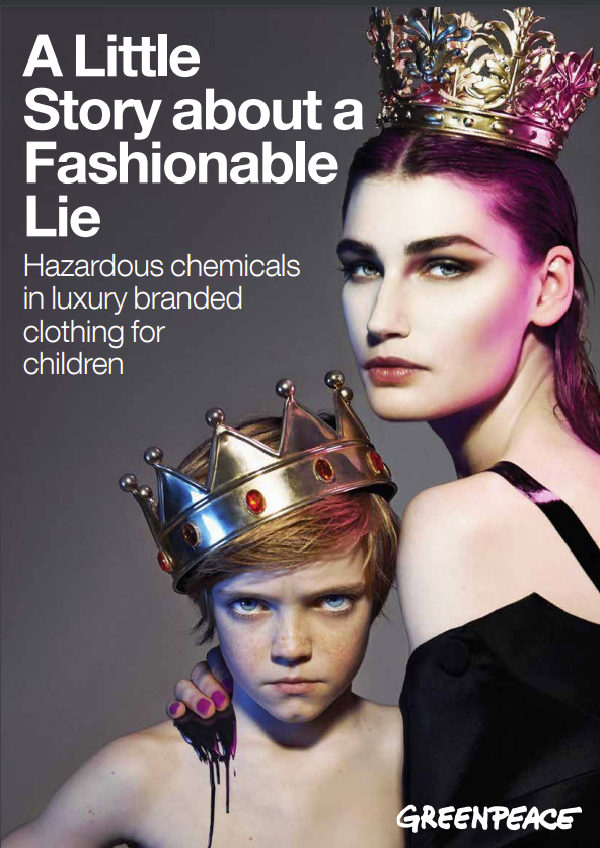

Recycling also does nothing to solve a problem both microscopic and enormous: microfibres. These tiny fragments of plastic shed from our clothes when we wash them, wear them or throw them out, and leak into our bodies and the natural world. Microfibres are found throughout ocean ecosystems, with a recent study discovering that 73% of microfibre pollution in formerly pristine Arctic waters is from synthetic fibres that could be coming from textiles.9 Graver still, microplastics have even been found in the placentas of unborn babies, affecting the human body in ways that are not yet fully understood.

The way forward

Unless we move away from the fossil fashion production model, we risk pushing past planetary boundaries in our quest for cheap fashion. We will be entirely unable to cope with the mountains of clothing waste produced by the system, and reliance on fossil fuels will contribute to catastrophic levels of climate change. We cannot rely on the fashion industry to address this issue by voluntary means, especially as our investigation reveals that numerous initiatives in the ‘sustainable apparel’ sector try to portray polyester as more sustainable than natural fibres. This is not just marketing – these assessments are being used to make concrete decisions about future fibre demand and production. For example, brands signing up to the Global Fashion Agenda (GFA) Pulse intend to replace 30% of their cotton with polyester by 2030.

It is more urgent than ever to find effective legislative solutions to put the fashion industry on a more sustainable track and to push towards great circularity. The Covid-19 pandemic has revealed the cracks in the fashion industry’s faulty and short-termist business model, but the crisis also represents an opportunity for change. Fashion brands have to become accountable for what happens in their supply chains and they must shoulder full responsibility for what happens to their clothes at the end of life – in line with the polluter pays principle.

The European Commission has announced that this year it will publish a comprehensive EU strategy for textiles. This strategy creates a crucial opportunity to tackle the global impact of fast fashion, by decoupling the fashion industry from fossil fuels and making sure the industry shifts to responsible production based on the use of sustainable fibres, and by slowing down production through a switch to more durable clothes with greater levels of reuse and effective recycling. Governments worldwide should follow suit and commit to developing ambitious legislation for the textile sector.

Do you want to discover more on this topic? You can read the book above for more.