BCcampus Open Education believes that education must be available to everyone. This means supporting the creation of free, open, and accessible educational resources. We are actively committed to increasing the accessibility and usability of the textbooks we produce.

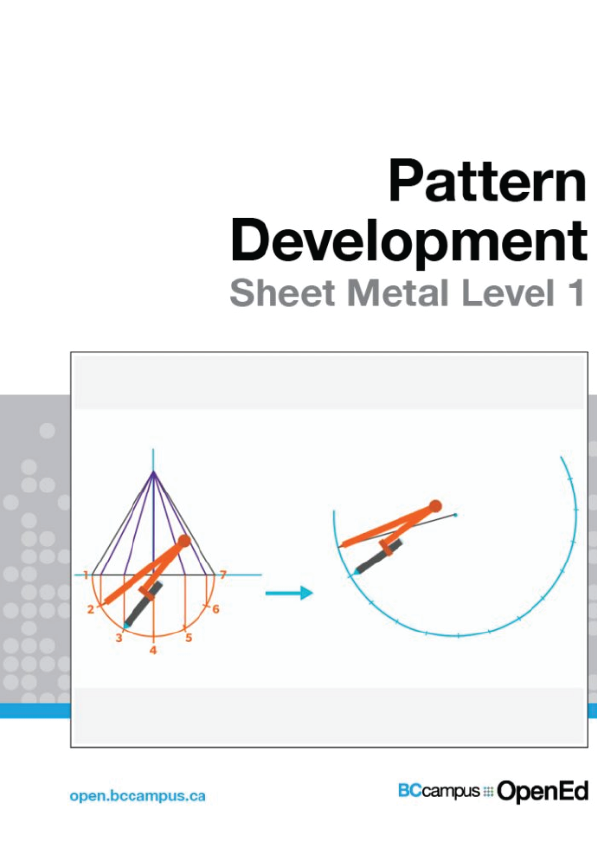

Pattern Development: Sheet Metal Level 1 by Brian Coey was funded by BCcampus Open Education.

BCcampus Open Education began in 2012 as the B.C. Open Textbook Project with the goal of making post-secondary education in British Columbia more accessible by reducing students’ costs through the use of open textbooks and other OER. BCcampus supports the post-secondary institutions of British Columbia as they adapt and evolve their teaching and learning practices to enable powerful learning opportunities for the students of B.C. BCcampus Open Education is funded by the British Columbia Ministry of Advanced Education and Skills Training and the Hewlett Foundation.

Open educational resources (OER) are teaching, learning, and research resources that, through permissions granted by the copyright holder, allow others to use, distribute, keep, or make changes to them. Our open textbooks are openly licensed using a Creative Commons licence and are offered in various eBook formats free of charge, or as printed books that are available at cost.

For more information about open education in British Columbia, please visit the BCcampus Open Education website. If you are an instructor who is using this book for a course, please fill out our Adoption of an Open Textbook form.

Introduction

When wanting to build a project, we need to first imagine it. The process of pattern development gives us the ability to take that visual representation and actually create the object. It allows us to turn two-dimensional metal, into three-dimensional objects, which is the basis for everything we fabricate.

As a sheet metal worker, we work with different lines, angles and shapes. We work with geometry. Be it in the field or in a shop, geometry is a tool we use in many different ways. From creating 2D patterns of 3D objects, to making sure roof panels are installed square, to locating duct runs and penetrations, geometry is used everyday by a sheet metal worker. This is the foundation for which all layout is done. Craftspeople who excel at this stage are able to quickly transform any complex ideas into reality.

Points, Lines, Angles and Shapes

In geometry we deal with many different shapes. All shapes are made up of various points, lines and angles.

Lines

We can define a point (A) as a single location on a shape or line.

A line (A-B) is made up of 2 points. There are different types of lines:

- horizontal (level with the horizon),

- vertical (up and down, also known as plumb),

- tilted (neither vertical nor horizontal), and

- arcs (a line from a radius point).

We also have lines which are parallel or equal distance apart and lines which are perpendicular or at right angles to one another

Angles

An angle is formed at a point at where 2 lines meet (vertex). We deal with three different types of angles:

- Right angles are at 90° and are very important in layout,

- Obtuse angles, which are greater than 90°, and

- acute angles, which are smaller than 90°. Shapes

Shapes

With a combination of points, lines, and angles, we start to create shapes. Triangles (A-B-C), squares or rectangles (A-B-C-D), and circles are some of the most common shapes seen in the sheet metal industry. It is a combination of points, lines, and angles that make up different shapes —or in our case, our patterns.